Warped Manifold: 2020 Land Rover Defender P400

Over the last few months I’ve been noticing a chatter type noise when cold starting my 2020 Land Rover Defender P400. At first it was intermittent and only at the occasional cold start. It began in the middle of Summer and I had thought maybe it was an A/C compressor or belt noise.

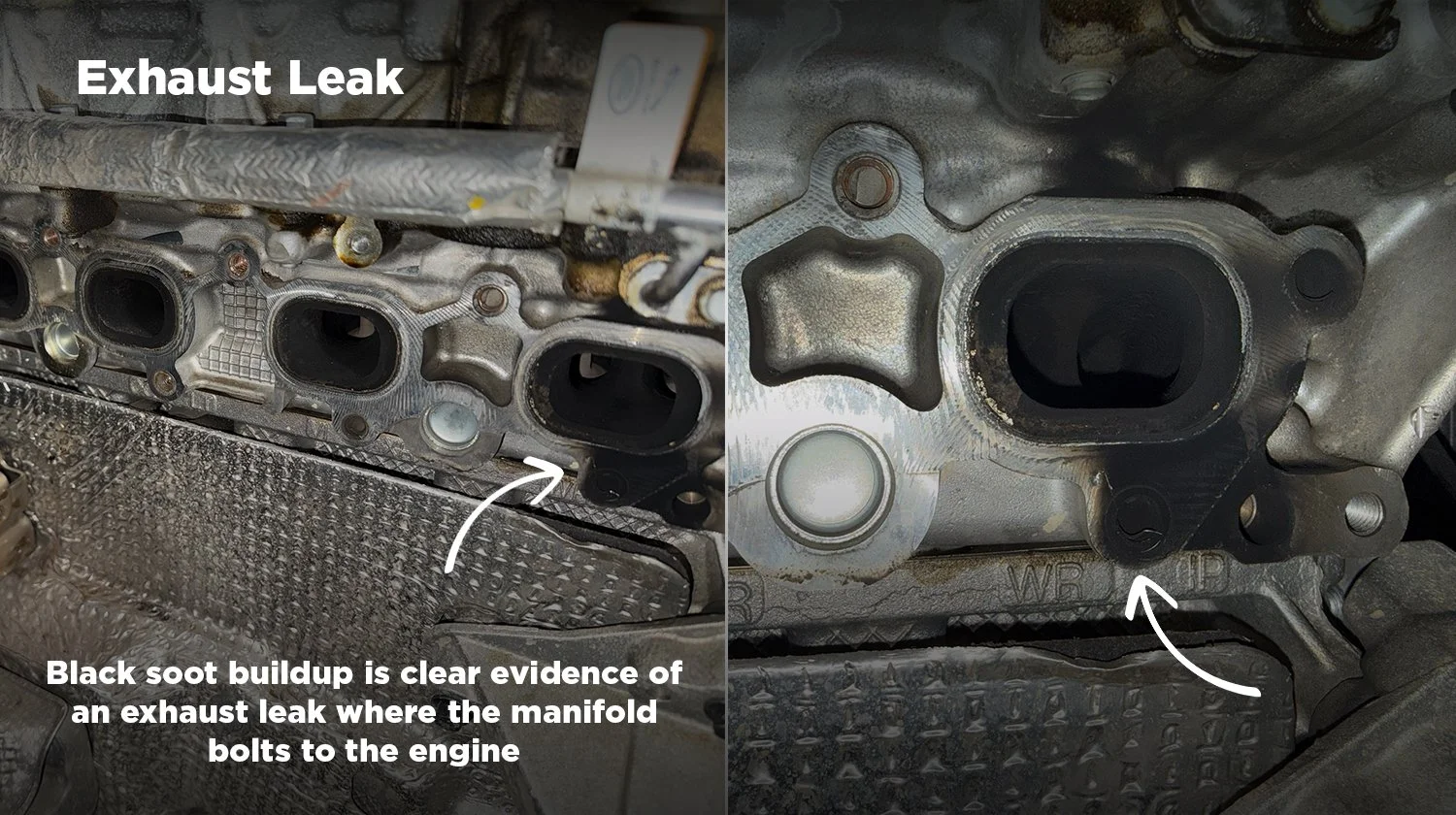

When we got the car up on the hoist with all the skid plate off we confirmed the noise was actually an exhaust leak coming from the exhaust manifold and turbo area. After a few attempts to tighten the turbo to the manifold clamp, we decided the turbo needed to be removed for closer inspection.

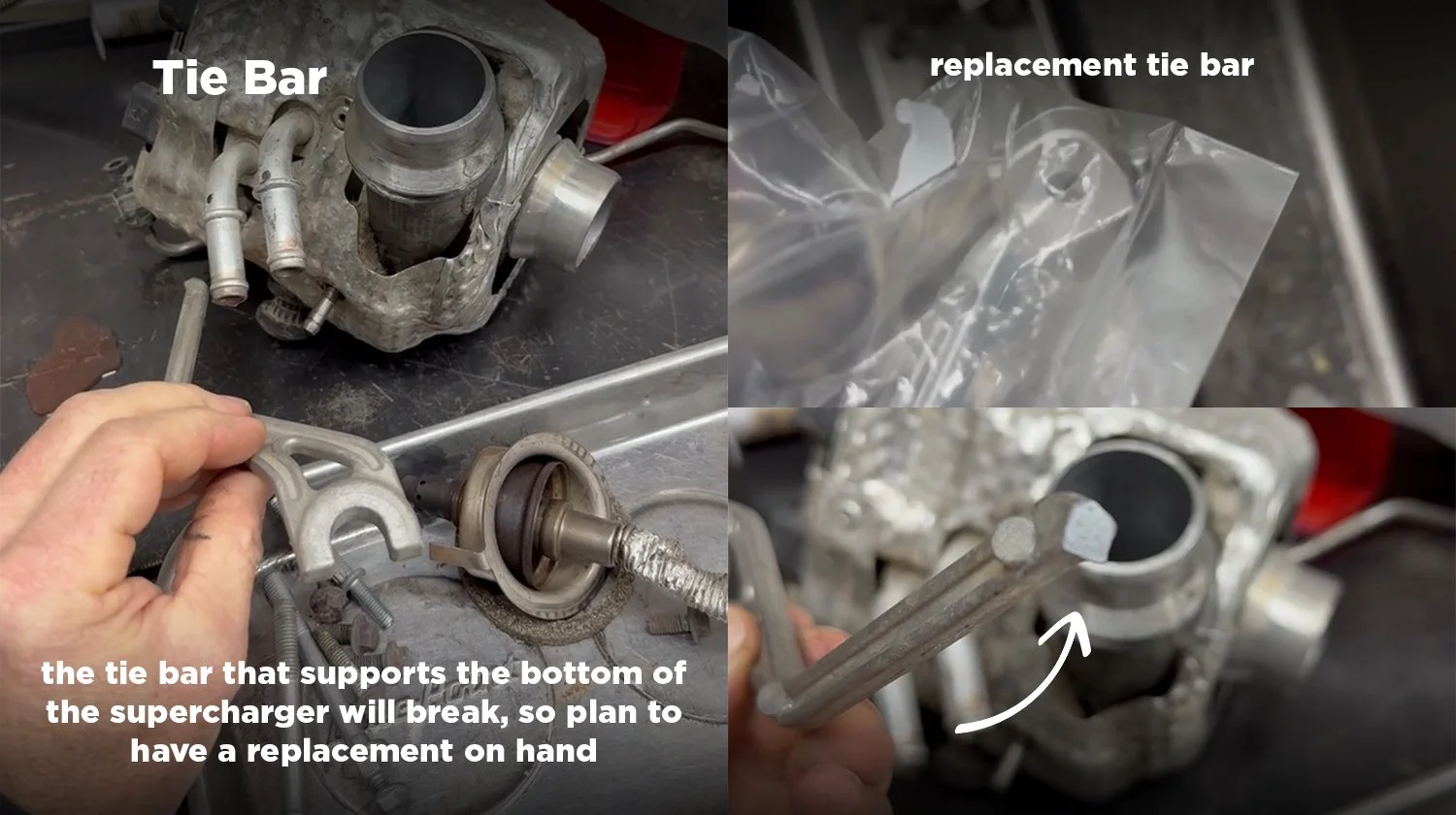

Once we had all the bolts and gaskets ready to go we started the big disassembly. There is so much stuff packed into this engine: it is tight! One care point to note is the fragile tie bar that supports the bottom of the electric, 48-volt supercharger, it's gonna break, so plan to have one on hand!

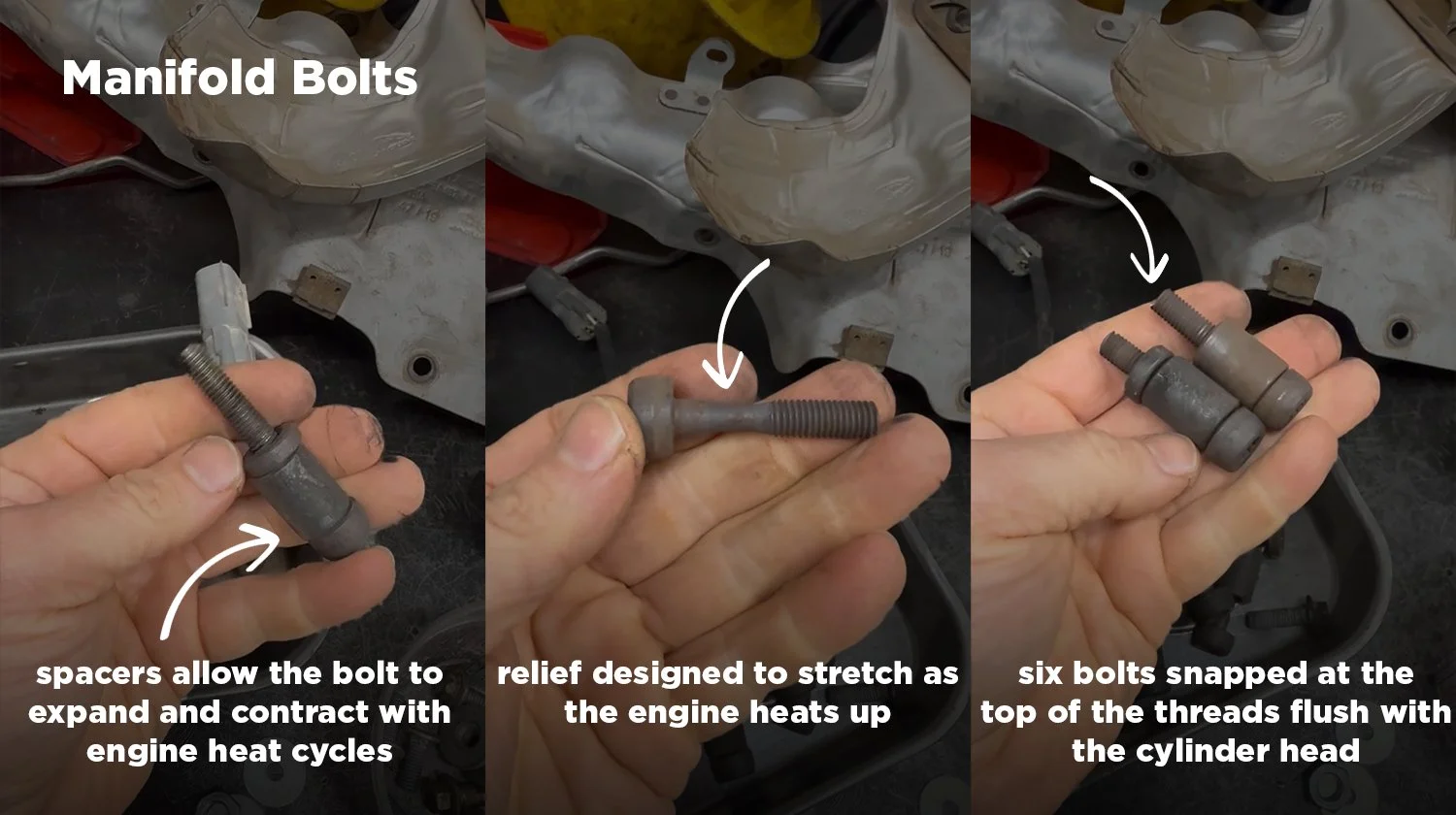

With everything out of the way we could now see the top of the exhaust manifold. To our surprise there were a few broken bolts laying on top. It turns out that some of the exhaust manifold bolts that secure it to the cylinder head had broken and fallen out. Now we are starting to understand what’s causing the exhaust leak and noise at cold start.

Once we got the exhaust manifold out and on the bench we had found a total of SIX broken exhaust manifold bolts. We also checked the manifold with a straight edge and confirmed the manifold was warped.

Our shop foreman worked some magic and was able to get all six out using a technique where you weld a nut to the stud in the cylinder head. With the combination of heat from welding and the mechanical force from the welded nut they all came out after a few tries and thankfully no drilling was required!

We separated the turbo from the manifold and took it to the machine shop. The machine shop built us a special mounting jig to firmly mount and support the manifold in the CNC milling machine. This took a few days and we now have a special tool to make the machine shop portion of this repair a quick one day turn around.

During reassembly, we did snap one of the new manifold bolts which was odd and why careful attention to the procedure and torque values is critical. We are looking into the options to get some high strength studs and upgrade from the factory bolts. Using studs is common in high performance applications and there should be no issues making this change.

While there is no way to prevent this from happening, catching it early could save you from having to replace the turbo assembly. We’ve only put about 2000km on our Defender since this repair, but other than a quick check over and topping up the coolant, all is well! We will post another update after 10,000km.